The twistable, bendable, easy-to-make device marks a step beyond current technology

Peter Wilson

Sun

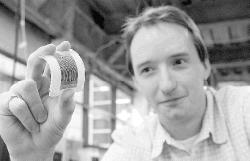

CREDIT: Stuart Davis, Vancouver Sun Kevin Stanley of the Institute for Fuel Cell Innovation holds small fuel cell that has potential output of more than 200 milliwatts, enough to power low-wattage items such as a cellphone or MP3. It would run on methanol.

Vancouver researcher Kevin Stanley holds the prototype flexible micro fuel cell between his thumb and finger.

He pushes its ends together and it bends into an arc. Then he takes it in two hands and makes it twist in the middle.

Finally, Stanley lets the fuel cell — with just seven square centimetres of active area — fall to a countertop. It doesn’t come apart. It doesn’t shatter.

Call this breakthrough fuel cell technology with a twist — and a bend, and even a bit of a bounce.

Oh, and it should be easy to manufacture as well.

Within a few years the descendants of this rugged, flexible methanol-based mini fuel cell could be powering everything from your MP3 player to your PDA to your cellular phone to your digital camera.

And it’s a distinct departure and almost certainly a technical step ahead of the recently hyped 5.6-cm-long Toshiba “world’s smallest” fuel cell, created using traditional, rigid technology.

That device was said by Toshiba to be able to power an MP3 audio player for about 20 hours on a single charge of methanol fuel.

“What Toshiba has done is more traditional architecture optimized to the maximum,” said Stanley. “We’re looking at taking it beyond that.”

Two years ago, Stanley, a project leader at Vancouver’s National Research Council Canada Institute for Fuel Cell Innovation Research, built a prototype similar to Toshiba’s and realized that he’d about reached the size limits of traditional design.

“That’s something we call plate-and-frame, very much like taking something that Ballard has, and shrinking it down,” said Stanley.

To put it simply, plate-and-frame — in which the various elements of the fuel cell are compressed in layers — was getting in the way of miniaturization, crucial for fuel cell use in devices like cellphones and PDAs.

“So what we essentially tried to do was to come up with a compressionless fuel cell, “ said Stanley, who is completing his PhD in engineering at Simon Fraser University.

The other goal, necessary for eventual commercialization, was to make the fuel cell easy to manufacture. Right now fuel cells are hand assembled, which can account for 80 per cent of the cost.

“At the end of the day, these things will be in commercial electronics, whether it’s in 2005 or 2006 or 2010,” said Stanley. “You will need to produce hundreds of millions per month.”

The compressionless part turned out to be tricky, because if compression is lessened in a fuel cell the power can drop.

“If you let everything mellow out and relax and take away the compression then your resistance increases dramatically and your fuel cell no longer operates efficiently,” said Stanley.

Stanley and his team came up with new materials and new methods and, along the way, worked out a way to have the fuel cells manufactured through a reel-to-reel printing process.

“As a side-effect our fuel cell is incredibly flexible because we weren’t able to use rigid materials,” said Stanley. “It had to be able to go with the flow, so to speak.”

The advantages of flexibility, said Stanley, is that the fuel cell can be twisted or bent to fit inside a small electronic device, or it could be a power source for something like a flexible computer screen.

Two patents have been applied for on the technology.

Another advantage of flexible micro fuel cells is that they protect against high humidity and the problem of water collecting in a fuel cell.

“In one of these compact little micro mini cells the weather outside is the weather outside,” said Stanley.

While the fuel cell will likely make its way into commercial development, Stanley emphasizes that, at the moment, it’s a research project and that there are hurdles on the business side as well as the technology side.

One of these is making the power source for the fuel cells easily accessible to buyers.

“In order for this to be a big success you’ve got to have little methanol cartridges in every 7-Eleven in North America,” said Stanley. “That’s going to slow things down as well.”

Stanley said that initially it’s likely that the flexible micro fuel cells will be found in niche markets.

“The U.S. military is throwing ridiculous amounts of money at fuel cells,” said Stanley. “You see those guys in Afghanistan, half the stuff they’re carrying around is batteries. I think its about 40 pounds for a six-hour mission. They’d like to reduce that load.”

© The Vancouver Sun 2004